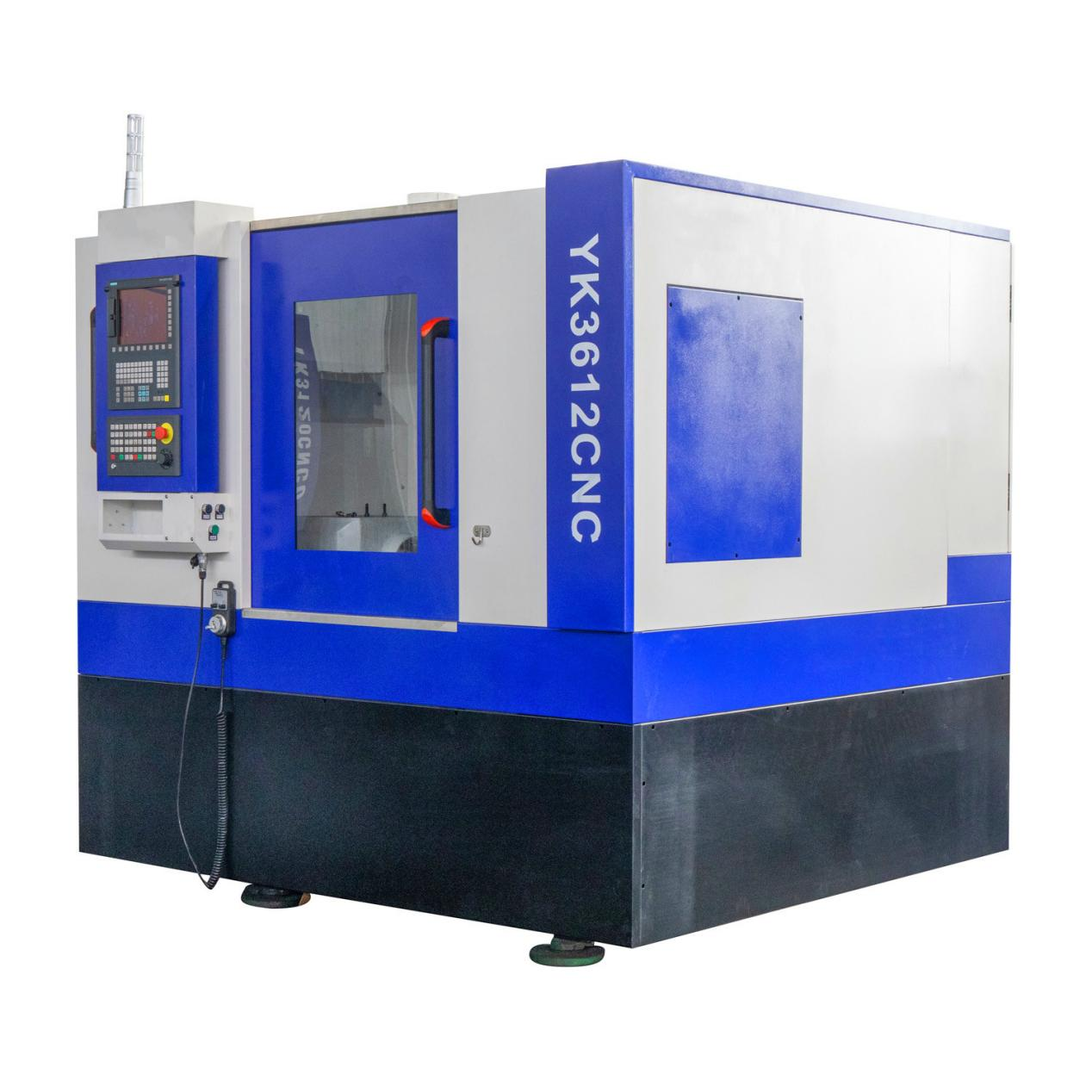

YK3612 Horizontal Gear Hobbing Machine for 0.5-2.5modules cutting

YK3612 Horizontal Gear Hobbing Machine for 0.5-2.5modules cutting

CHINA GEEPRO YK3612 CNC 6 axis Horizontal Hobbing Machine

Cutting Max Dia 120mm

Hobbing Max Modules 2.5m

This gear hobbing machine is suitable for cutting such gears and gear shafts at smaller diameter but with large modules and double-open bush-embracing structure is adopted for the rear column of this machine, which helps a lot to cut large gear shafts.

This machine is suitable for cutting such workpieces, on continuous dividing tooth methods, as cylindrical straight gears, helical gears, worm gears & sprocket wheels, synchronous pulley, spline shafts in batch and/or single production.

Besides, Herringbone gears without clearance groove can also be machined on this machine by using finger-milling cutter.

Indexing device for single tooth is designed and set on this machine to achieve milling gears circularly and automatically by using disc-type milling cutters or finger-type milling cutters.

This machine is widely used for generating gears that are used in industries of mines, steels, wind powers, ships and so on.

Performance and Feature

1. With vertical design, the worktable can move in radial as radial feed movement.

2. Electrical system with fail-safe control and low failure rate is controlled by PLC of OMRON.

3. The modular valves available from Northman has high reliability and low failure rate in order to be convenient to diagnose failures and maintain hydraulic system.

4. The worktable is fitted with double-start worm as its index gearing. It is suitable for cutting the workpiece with less-teeth.

5. The hob spindle adopts circulating lubrication to ensure sufficient and reliable lubrication for spindle bearings in order to prolong their service life. Meanwhile circulating oil can quickly remove heat caused by spindle running to insure high rotary accuracy for the spindle.

6. Supply with special attachments according to the customers' special order.

7. Tangential hob head, hydraulic fixtures, workpiece arbors, live center, shift hob head.